Supported by advanced robotics technology, XVEL robots offer exceptional features in navigation, management and maintenance. Their easy-to-use application and full automation make them extremely user-friendly. Thanks to cloud-based management, these robots are not only efficient, but also extremely easy to maintain, making them an industry leader.

Get to know better the technology of our cleaning robots

Unlimited mapping and dynamic localization

After the first deployment, XVEL robots will start navigating the space and create a semantic map of the place. No location marker, laptop connection or professional engineer is needed to map a place.

Backed by high-precision LiDARs and cameras, XVEL robots offer industry-leading mapping and localization capability in terms of accuracy, robustness and performance. In a dynamic environment, XVEL robots will locate themselves and update the map in real time.

Mapping and localization

Environmental perception

Path planning

Traffic control

3D scanning combined with artificial intelligence

XVEL service robots can scan the surrounding environment using perception algorithms based on deep learning. They continuously learn the landscape of their surroundings and make advanced behavioral decisions.

Trained on millions of real-world images, they can identify different types of obstacles and debris with 99% accuracy and make appropriate behavioral decisions. For example, in the case of low obstacles, they would navigate around electrical wires, but drive over speed bumps.

In automatic spot-cleaning mode, the robot will clean those areas it can, and send messages to operators via the app if it encounters waste it can’t clean.

Flexible

planning

paths

Path planning for cleaning robots is the most difficult, as the path should fully cover the area of operation, adapting to environmental changes and dynamic obstacles. XVEL provides industry-leading planning algorithms with 5 modes: Teach & Follow, Sketch, Auto Cover, Real-time Auto Cover and Auto Spot Cleaning. This gives users the freedom to customize cleaning plans. They can also divide the environment into smaller regions and choose the most appropriate path planning mode for each region depending on the situation.

Teach & Follow

Record and repeat: An operator programs a path by manually directing the robot, and the robot records the generated path in real time. The robot duplicates the recorded path in subsequent cleaning tasks, automatically avoiding new obstacles.

Real-time AutoCover

Spiral Filling Backtracking: Similar to Auto Cover, but the operator doesn't have to guide the robot to deploy. Instead, he draws a box on the map to define the cleaning area, and the robot will automatically clean all the traversed areas inside the region in each operation.

Auto Spot Cleaning

Automatic point-to-point: the robot continuously scans the cleanliness of the nearby floor and automatically performs spot cleaning when it detects waste or stains. By cleaning only where it's needed, it provides up to 4x improvement in efficiency and significantly reduces water and energy consumption.

AutoCover

Fill mode: The operator manually steers the robot along the boundary of the area to be cleaned, after which the robot will automatically generate a zigzag path to fully cover the area in the most efficient way.

Sketch

Point to point: The operator draws a path, setting up a group of control points on the map, and the robot moves along it.

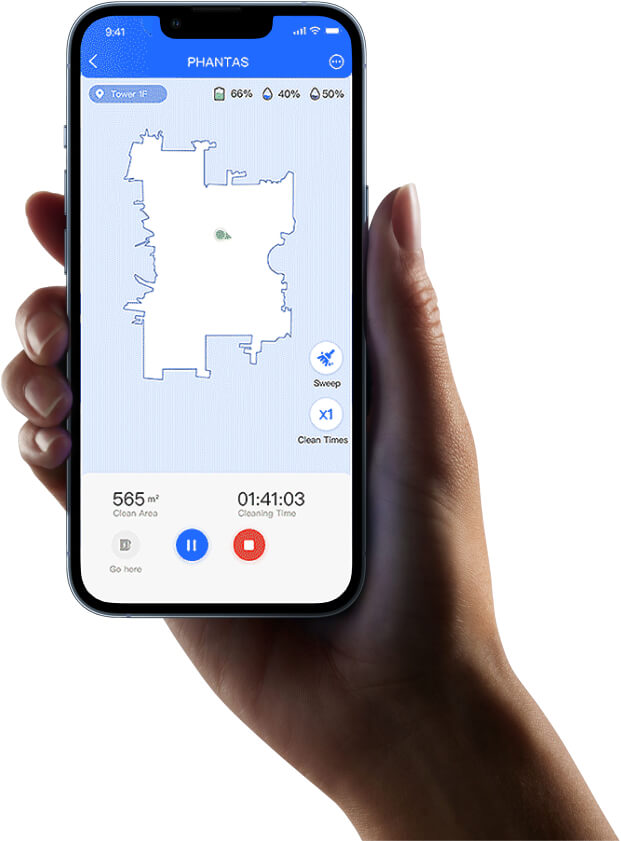

Control the cleaning robot on your smartphone

The dedicated app allows you to control floor cleaning from anywhere and anytime. It offers plenty of options, such as map editing, remote control, task scheduling, data reporting, etc.

Task planning

Set up a task in the app, and the smart cleaning robot will automatically start cleaning at the scheduled time.

Data reporting

Receive detailed reports on operational indicators and graphs of historical statistics through the app.

Map Editing

Edit your floor map by setting virtual walls or exclusion zones to avoid cleaning selected areas.

Remote operation of the robot

Remotely start, pause or end cleaning tasks on your smartphone.

Calling the elevator

Today, the Phantas, Vacuum 40 and Scrubber 50 series can be integrated with smart elevator systems via API, making autonomous elevator travel possible.

This has eliminated the need to keep staff on standby to maneuver a heavy robot from floor to floor, and cleaning has reached a whole new level, enabling seamless floor cleaning throughout the building without human intervention.

Docking stations

XVEL robots are paired with optional docking stations to increase durability and reduce the need for manual intervention. Docking stations are available for the Vacuum 40 series for automatic charging. Phantas, Scrubber 75 and 50 series are paired with optional work stations for automatic charging, refilling and discharging.

The deployment of on-site docking stations eliminates the need to send someone on-call for service and maintenance while the robot is in operation. Independence from manual involvement allows the robot to perform tasks at any time, even outside of working hours. It allows facility owners to deploy robots late at night, when there is little or no foot traffic, for the best cleaning results.